It is necessary to make a few measurements before welding the two halves together to insure proper length, diagonal, and wheel track measurements. You may want to hold the two halves together with splints and c-clamps while you measure. Be sure the joint does not sag below the level line of the chassis. This will cause a poor fit of the body. If in doubt, weld joint should be raised instead of sag.

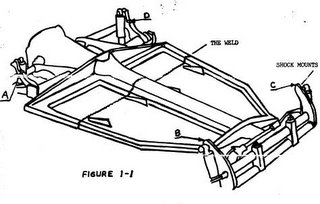

Wheel alignment is directly affected by the cut made in shortening the belly pan. Slight error may be corrected when the pan is welded. Alignment may be accomplished in the following manner (see figure 1-1):

- Measure from points A to B, A to C.

- Measure from points D to C, D to B.

All measurements should be within 1/16-inch tolerance.

After you tack the belly pan in three or four equally spaced places, you should measure over again the same as before.

After welding the joint in the belly pan you will notice the rear half is wider than the front half. When welding you should stop about 8” from the side rails to allow room to cut and trim as shown in figure 1-2.

When all the welding of the top side of the chassis is complete, turn the chassis up on it’s side and weld the bottom side of the belly pan. Make certain that the area of the tunnel has a good weld joint as this is the main support of the belly pan.

No comments:

Post a Comment